Convert Seawater To Drinking Water

Built for Residential Homes, Docks, Commercial Businesses

Built for Residential Homes, Docks, Commercial Businesses

For nearly two decades RainDance Water Systems has provided sea water desalination systems throughout the US & Worldwide

From California - Florida - Texas - Singapore - Oman - Belize - Bahamas - Virgin Islands - Hawaii

From California - Florida - Texas - Singapore - Oman - Belize - Bahamas - Virgin Islands - Hawaii

Sea Water Desalination Purification Equipment

Built-To-Order: There are significant differences in the equipment used for removing most of the dissolved solids from Sea Water & Oceans and from most surface or well waters. Seawater units are referred to as Desalination Systems and surface/well water units are called reverse osmosis (RO) units. The laws of physics require approximately 1 psi driving force for each 100 mg/l of solids dissolved in the water to be treated. Seawater has about 35,000 mg/l of dissolved solids so to obtain the first drop of permeate water a pressure of 350 psi is required. Reverse osmosis units on the other hand normally treat water where the dissolved solids content is in the area of 6,000 mg/l or less. The required pressure for that first drop of water for 6,000 mg/l is 60 psi. To insure an adequate flow of water from the respective devices seawater units usually operate in the area of 1,000 psi and RO units in a range of 150 to 250 psi. This additional pressure requirement for seawater increases the required strength of almost all components and requires much larger pumps. Also, seawater is extremely corrosive so the materials of construction for seawater units must be non-corrosive. All of these differences cause the cost of seawater units to be much higher than the cost of an equivalent gallon output RO unit.

|

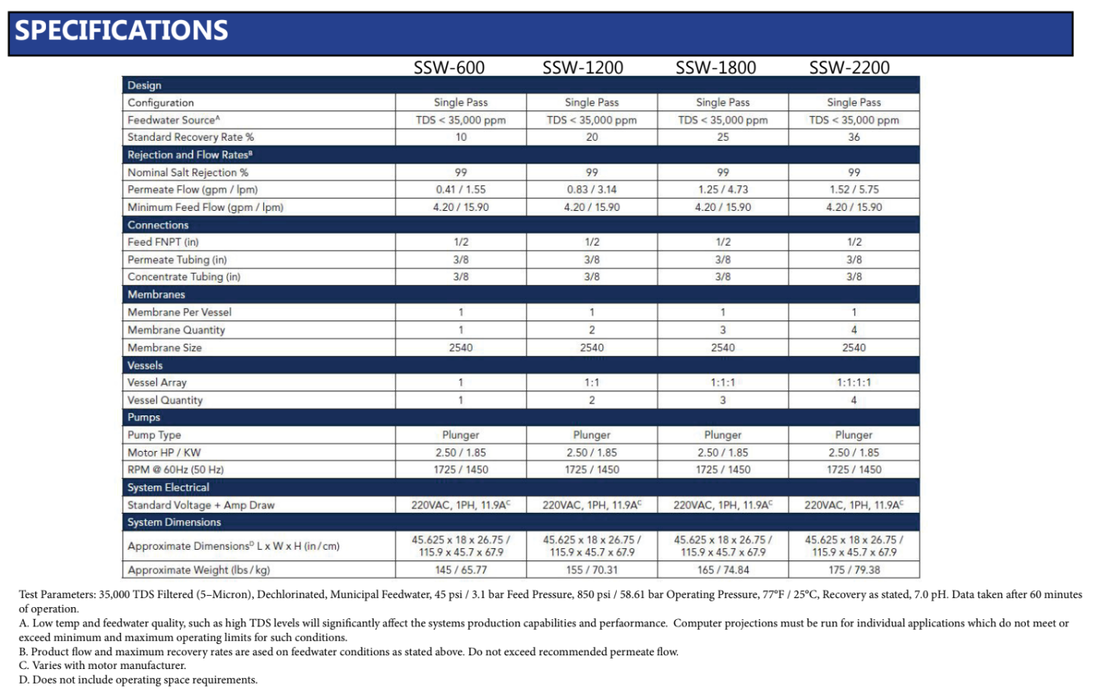

RainDance-SSW-600 Seawater Desalination System

Capacity: 600GPD (24hr) Max TDS: 50,000ppm Turn Seawater Into Drinking Water Applications: Whole House, Vacation Homes, Docks, Resorts, Cottages, Emergency Back-Up Seawater Filter Prices Start @ $16,995 |

RainDance-SSW-1200 Seawater Desalination System

Capacity: 1,200GPD (24hr) Max TDS: 50,000ppm Turn Seawater Into Drinking Water Applications: Whole House, Vacation Homes, Docks, Resorts, Cottages, Emergency Back-Up Seawater Filter Prices Start @ $17,995 |

RainDance-SSW-1800 Seawater Desalination System

Capacity: 1,800GPD (24hr) Max TDS: 50,000ppm Turn Seawater Into Drinking Water Applications: Whole House, Vacation Homes, Docks, Resorts, Cottages, Emergency Back-Up Seawater Filter Prices Start @ $18,995 |

RainDance-SSW-2200 Seawater Desalination System

Capacity: 2,200GPD (24hr) Max TDS: 50,000ppm Turn Seawater Into Drinking Water Applications: Whole House, Vacation Homes, Docks, Resorts, Cottages, Emergency Back-Up Seawater Filter Prices Start @ $19,995 |

Product Features

Important: A separate seawater delivery pump (not included) is required to deliver seawater to the desalination system at a minimum of 5gpm @ 30psi.

How It Works: Pressurized water from your seawater pump first enters the integrated sediment prefilter to provide extra membrane protection from dirt, sand, and debris. Additional pretreatment for excessive minerals or other contaminants may be needed to extend the life of the system. Prefiltered water then enters the desalination RO system to purify the water.

Purified water comes out of the RO system as a small stream, so a separate product water storage tank and repressuization pump is required to provide pressurized water to your taps. Purified water will begin filling the nearby product water storage tank until the included float switch shuts the entire system off. When there is a demand for water, the repressurization delivery pump is activated and draws water from the storage tank to your taps. If enough water is used to the point where the float switch is activated, the RO system will automatically turn on and begin replacing the water that has been depleted in the tank.

How Much Water Does It Produce: We offer a range of sizes including 600gpd, 1,200gpd, 1,800gpd, and 2,200gpd seawater desalination systems.

Computer Controller: Monitors several functional conditions and regulates operation of the high pressure pump and control valves. The controller is connected to sensors which, depending on their state, allow the cyclic production of purified water or prevent operation due to abnormal conditions. The standard configuration of the controller monitors feed water supply pressure for minimum level, product water storage tank level for system start/stop conditions and product water conductivity for maximum set point value and for digital front panel display. Additional optional parameters that the controller is capable of monitoring include main pump high pressure set point, low feed water tank level and membrane flush cycle occurrence and duration. Front panel buttons and digital display allow operator adjustment of set points and flush parameters.

Automatic Membrane Flush: When the desalination system stops running, the residual water inside the membrane vessel will have a very high salt content, much higher than the feed water since it is concentrate or brine. If left this way that salt content will go through the membrane by osmosis so you will have salty water on the product side of the membrane. The flush feature flushes the seawater purifying membranes for several minutes after every shutdown protecting the membrane from high mineral build-up.

Salinity Monitoring: Automatic electronic monitoring. Temperature compensated with the digital continuous readout. The salinity monitoring components of the system provide TDS readout in ppm (parts per million) of product water. Salinity Range: Designed for seawater use up to 50,000PPM TDS (NaCl) (typical seawater salinity is 35,000 ppm).

Seawater Durability: The desalination system is equipped with premium components that offer durability for extreme operating conditions, including a high grade corrosion resistant powder coated aluminum frame, fiberglass membrane housings, 316L Stainless Steel high pressure pump, tubing, and fittings. Each component of the seawater system has been chosen for its strength and reliability under high pressure, high salinity environments.

We Also Offer The Following Accessories: UV ultraviolet water disinfection systems for the removal of viruses and bacteria, hard water and scale prevention pretreatment systems, water storage tanks, repressure delivery pumps to provide pressurized water from your storage tank to your application and more.

Important: A separate seawater delivery pump (not included) is required to deliver seawater to the desalination system at a minimum of 5gpm @ 30psi.

How It Works: Pressurized water from your seawater pump first enters the integrated sediment prefilter to provide extra membrane protection from dirt, sand, and debris. Additional pretreatment for excessive minerals or other contaminants may be needed to extend the life of the system. Prefiltered water then enters the desalination RO system to purify the water.

Purified water comes out of the RO system as a small stream, so a separate product water storage tank and repressuization pump is required to provide pressurized water to your taps. Purified water will begin filling the nearby product water storage tank until the included float switch shuts the entire system off. When there is a demand for water, the repressurization delivery pump is activated and draws water from the storage tank to your taps. If enough water is used to the point where the float switch is activated, the RO system will automatically turn on and begin replacing the water that has been depleted in the tank.

How Much Water Does It Produce: We offer a range of sizes including 600gpd, 1,200gpd, 1,800gpd, and 2,200gpd seawater desalination systems.

Computer Controller: Monitors several functional conditions and regulates operation of the high pressure pump and control valves. The controller is connected to sensors which, depending on their state, allow the cyclic production of purified water or prevent operation due to abnormal conditions. The standard configuration of the controller monitors feed water supply pressure for minimum level, product water storage tank level for system start/stop conditions and product water conductivity for maximum set point value and for digital front panel display. Additional optional parameters that the controller is capable of monitoring include main pump high pressure set point, low feed water tank level and membrane flush cycle occurrence and duration. Front panel buttons and digital display allow operator adjustment of set points and flush parameters.

Automatic Membrane Flush: When the desalination system stops running, the residual water inside the membrane vessel will have a very high salt content, much higher than the feed water since it is concentrate or brine. If left this way that salt content will go through the membrane by osmosis so you will have salty water on the product side of the membrane. The flush feature flushes the seawater purifying membranes for several minutes after every shutdown protecting the membrane from high mineral build-up.

Salinity Monitoring: Automatic electronic monitoring. Temperature compensated with the digital continuous readout. The salinity monitoring components of the system provide TDS readout in ppm (parts per million) of product water. Salinity Range: Designed for seawater use up to 50,000PPM TDS (NaCl) (typical seawater salinity is 35,000 ppm).

Seawater Durability: The desalination system is equipped with premium components that offer durability for extreme operating conditions, including a high grade corrosion resistant powder coated aluminum frame, fiberglass membrane housings, 316L Stainless Steel high pressure pump, tubing, and fittings. Each component of the seawater system has been chosen for its strength and reliability under high pressure, high salinity environments.

We Also Offer The Following Accessories: UV ultraviolet water disinfection systems for the removal of viruses and bacteria, hard water and scale prevention pretreatment systems, water storage tanks, repressure delivery pumps to provide pressurized water from your storage tank to your application and more.

Do you have salt water intrusion but don't quite need a seawater filter?

We also offer brackish salty water reverse osmosis water purification packages - Details below

We also offer brackish salty water reverse osmosis water purification packages - Details below